TRIPOD, GANTRY SCANNER OR ROBOT MOUNTING

2100

PORTABILITY MEETS POWER AND VERSATILITY

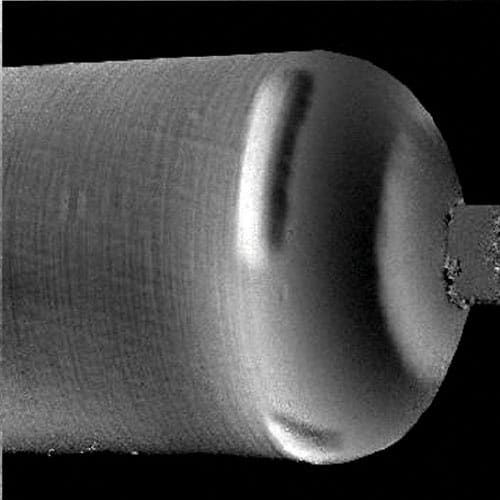

Designed for fast and accurate nondestructive inspection of structures, components and repairs.

Compact, rugged shearography camera

Lightweight and easy to use.

Exceptional image quality.

12-bit hi-definition sensor and diffraction limited optics.

Powerful defect analysis tools

Easily programmable image processing macros in LaserNDT 1.8.0 Software Suite for improved operator image analysis and reporting.

Versatile camera

Easily mounts to scan gantries, robots, crawlers, tripods, vacuum attachments, and customer defined test configurations.

Test configuration

All Mode Operation: Thermal, Vacuum, Vibration and Pressure Stressing.

Options

Test Part Stressing Systems, Test Chambers, Gantries, Workstations, and Robotic Scanners.

SPECIFICATIONS

System includes

Shear camera with a built-in 100 mw laser light source (Class IIIa), image processing computer, interconnect cables, tripod, transit case and Operator and Applications Manual

Optional equipment

Thermal Stress Systems TES-50 (500W) or TES-200 (2kW) with software control and adjustable radiant beam spread.

Table Mount, remote control Pan & Tilt, MQTT Robot Integration Software

Shear Camera Dimensions

12.0 x 4.0 x 5.5 in / 30.5 x 10.2 x 14.0 cm

Shear Camera

6.2 lbs. / 2.8 kg

Sensor

1628 x 1236 12 bit/30 fps

Power

100 to 240 VAC, 50/60 Hz20 amps maximum (with TES-200)

Operation Modes

Shearography testing with Thermal, Ultra Sonic or Accustic Vibration, Vacuum or Mechanical test part stressing Analysis and Measurement• Defect Location on test part• Image Integration and Z axis measurement

Shear Vector

Fully adjustable Shear Vector: 0-360 ?/0-10 ?

Image Calibration

Manual and Auto Cal., real-time readout of FOV, Scale, Shear Vector

Laser Light Source

100 mw, Class IIIa Laser Product

System Software

LaserNDT 1.8.0

Downloads

Patents: The LTI-2100 is manufactured in the USA under US and foreign patents 6,717,68; 5,257,088; 5,094,528. Additional patents pending. Specifications are subject to change.

Laser Shearography Certifications AIA NAS 410, ASNT SNT-TC-1A, ASTM E2581-07, EN 4179

INSPECTION APPLICATIONS

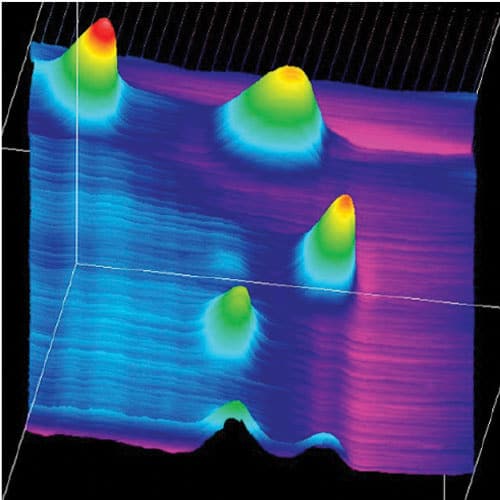

SHEAROGRAPHY IN ACTION

Shearography detects: Delaminations, Disbonds, Impact damage, Repair defects, Porosity, Cracks ,Fiber waves or wrinkles.

OUR FULL LINE OF SHEAROGRAPHY NDT SYSTEMS

Shearography can be applied to many applications, if we don’t have a system that works for you, we can custom build one that will.