OUR NDT TECHNOLOGY

- Disbonds, Unbonds, Delamination

- Core damage, Core splice disbonds, crushed core

- Impact Damage, Heat Damage

- Water Ingress

Test

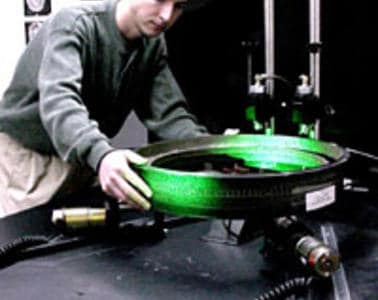

Shearography NDT - How it works...

- The camera captures the unstressed Reference image

- The IR Stressing device then heats the surface image

- The face sheet deforms more where it is unsupported by the core due to disbonds

- Local deformations are displayed in real-time

- Defects are shown in detail in the final Unwrapped image.

NDT Applications

Our engineers have extensive first hand knowledge of a broad range of materials, structures and NDT applications such as: aircraft engines, composite and honeycomb components, COPV tanks and rocket engines, helicopter rotor blades, marine, and spacecraft/launch vehicles.

Laser Shearography NDT technologyShearography

Laser NDT methods based on interferometric imaging, primarily holography and shearography, have seen growing acceptance since the mid 1980's. With the large increase in the use of composite materials and sandwich structures, the need for high speed, large…

Holography Technology

Holography has been used since the 1970’s for tire inspection. Before the development of electronic holography or electronic speckle interferometer (ESPI) cameras, film holography cameras were used in combination with vacuum stress.