DIGITAL HOLOGRAPHY INSPECTION SYSTEM

DH-8000

HOLOGRAPHY SYSTEMS

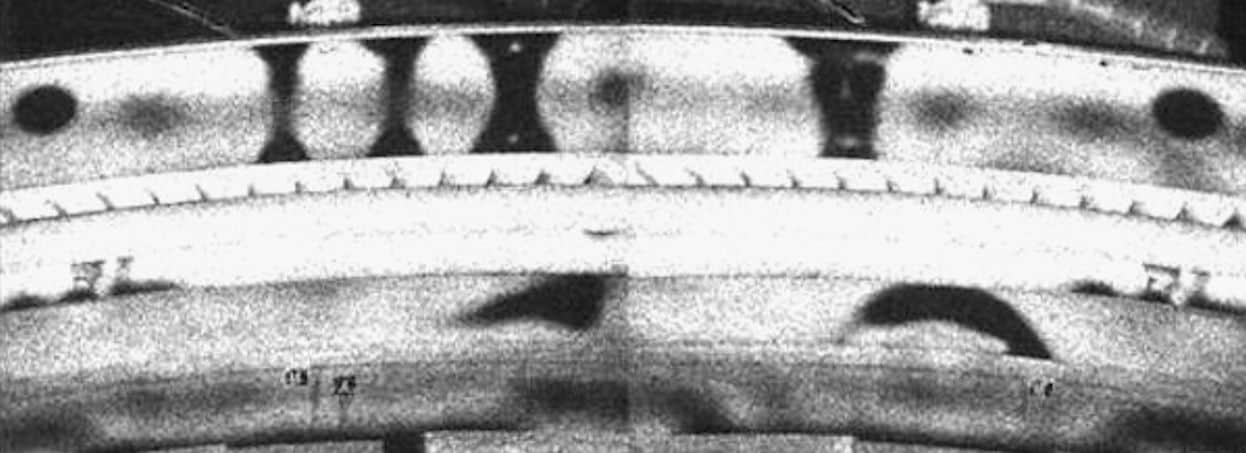

Ultrasonic Holography is a powerful NDT method for production inspection of metal bonded parts for turbine aircraft engines and medical implant devices.

Easy To Use

Programmable for easy operator setup and use.

Save Time

Optimizes inspection time. Save and recall multiple part test setups.

Powerful Image Processing

Mega Pixel Camera w/Laser Zoom

SPECIFICATIONS

System Features

- Full Automatic Production Testing

- Mega Pixel Camera w/Laser Zoom

- Test Modes: Manual, Automatic & R&D

- Adjustable Fixture to fit all

abradable shrouds, felt metal rings

and seals also ring sections - Zero Maintenance, 15,000 hr.

- Solid-State 150mw Laser

- Easy part set-up

- Image analysis tools

- Windows Operation

- LAN and Bar-Code optional

- Honeycomb Seal NDI Capability

- RTM Composites NDI Capability

- Designed and built in the USA

Materials / Applications

- Felt Metal Abradable Rings

- Honeycomb Seal Rings

- Plasma Sprayed Abradable Seals

- Abradable Shroud Rings & Seals

- RTM Composites

- Vane Clusters

Downloads

Meets Industry Standards i.e.:

The DH-8000 meets Pratt & Whitney Aircraft Specification BTM-11 Holography.

As an example, has inspected both F100 and JT9-D engine components and F117 RTM compressor stators.

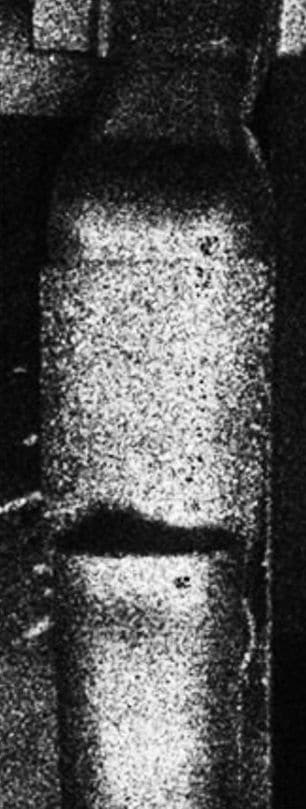

Disbonds appear dark in these Ultrasonic Holography results on a orthopedic Implant devices.

INSPECTION APPLICATIONS

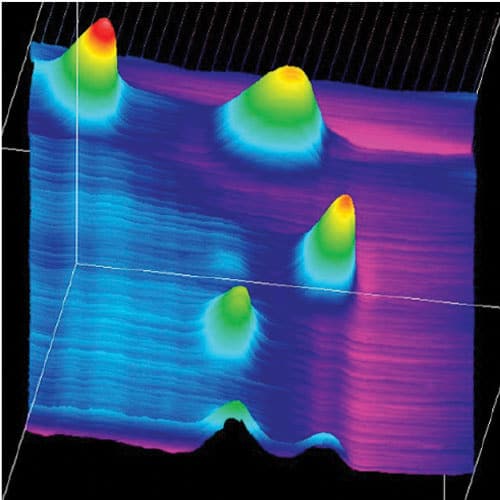

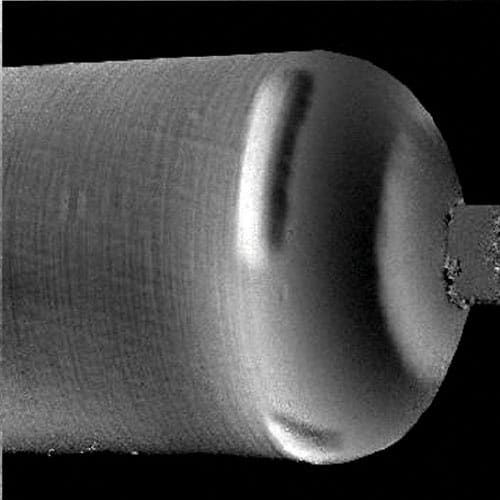

SHEAROGRAPHY IN ACTION

Shearography detects: Delaminations, Disbonds, Impact damage, Repair defects, Porosity, Cracks ,Fiber waves or wrinkles

OUR FULL LINE OF SHEAROGRAPHY NDT SYSTEMS

Shearography can be applied to many applications, if we don’t have a system that works for you, we can custom build one that will.