PORTABLE THERMAL LASER SHEAROGRAPHY

6200

Portable Thermal Shearography NDT System

Fast, Rugged, Easy to Use

Vacuum Attach

Test part in any orientation, easy to use.

Variety of Materials

Composite laminates, Honeycomb, Nomex, Rohacell, syntactic foam and cored panels and more

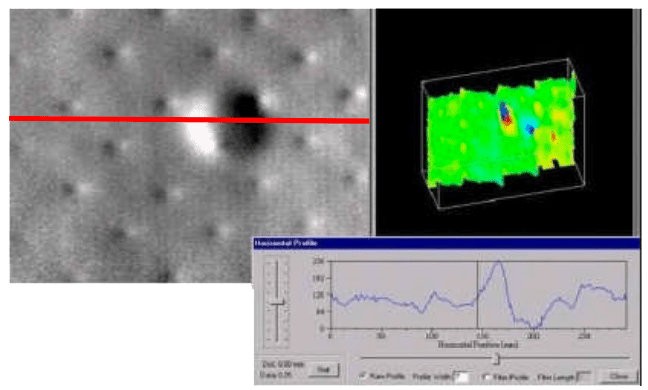

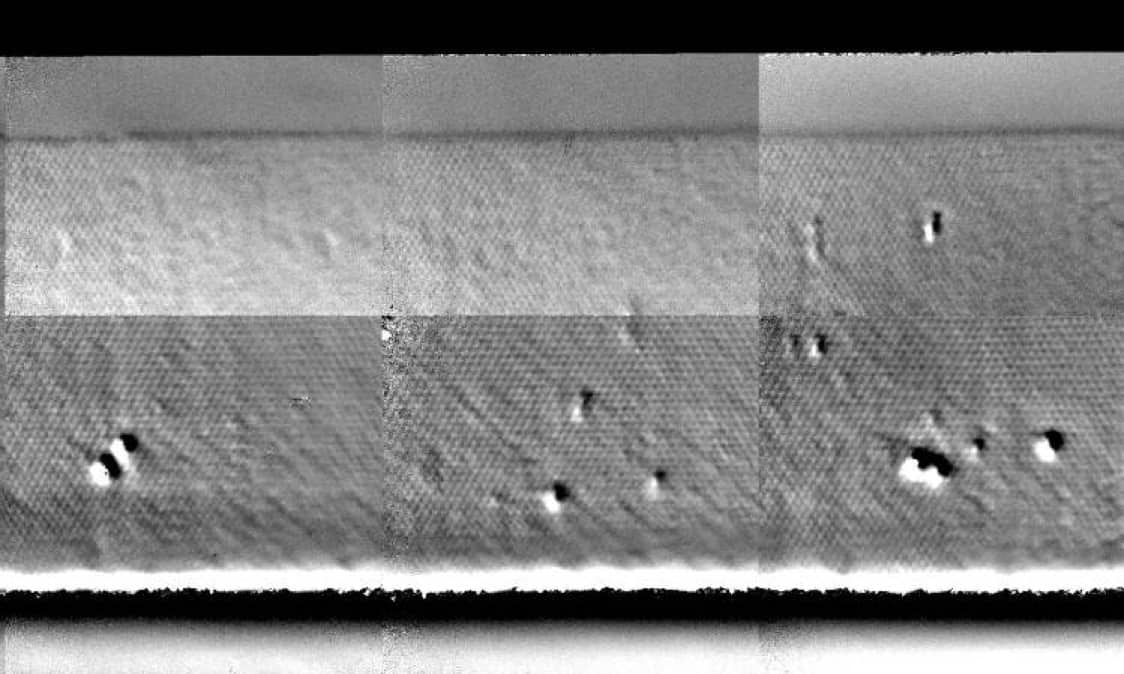

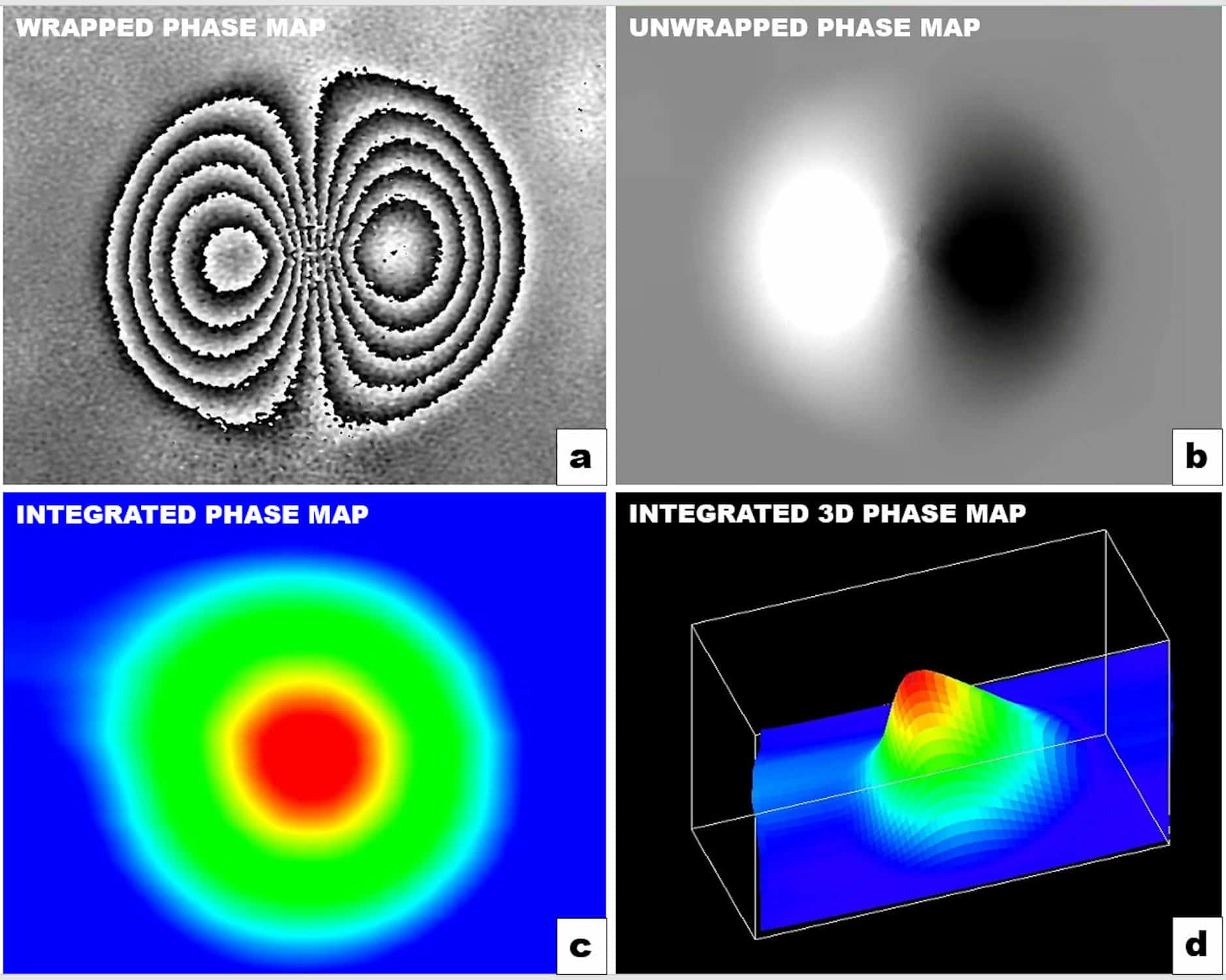

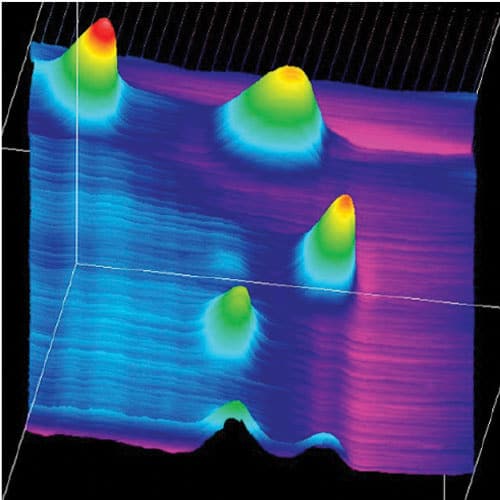

Powerful Image Processing

Real-time imagining of disbonds, delaminations, impact damage , porosity, heat damage, and more.

Speed

Increase in Aerospace manufacturing productivity.

SPECIFICATIONS

Technical Description

The LTI-6200 is a compact, portable thermal shearography system designed for the nondestructive inspection of aerospace composite repairs, structures and components.The LTI-6200 has a vacuum attach feature to allow operation in any orientation on-aircraft, on panels in the shop or on the bench. The patented cantilevered design allows inspection up to edges and corners on flaps, control surfaces, wing panels or cut-outs. The system features automatic operation with easily SAVE/RECALL NDE Procedure Macros, automatic exposure and image storage. The LTI-6200 includes the Inspection Head, Controller, cable set and transit case.

Optional Equipment

- Tripod and Adapter Plate

- MECAD-100, 200 Vibration Stress Units

- ACAD-100, 200 Acoustic Stress Units

- TS-100 Thermal Stress Unit

- Vacuum Windows and Generators

- LTI-9000 Vacuum Test Chambers

- Gantry and Mobile Lift Systems

Dimensions

Inspection Head

14 x 8 x 12 inches, 35.8 x 20.5 x 30.7 cm

Controller Case

20 x 16x 8 inches, 50 x 40 x 20 cm

Weight

Inspection Head

10 lbs., 4.5 kg.

Controller Case

13 lbs., 5.8 kg.

Other Specifications

Shear Camera Dimensions

4 x 6 inches, 10.3 x 15.4 cm

Displays (2)

4 x 6 inches, 10.3 x 15.4 cm, 1200 x 800 pixels, 32bit color,

16 inch/40cm, 1200 x 800 pixels, 32bit color

Power

100 to 240 VAC, 50/60 Hz 15 amps maximum (with TES-200)

Operation Modes

User Programmable Thermal Shearography , Analysis and Measurement, Image Overlay

System Software

ThermalShear 2.0

Downloads

Patents: The LTI-6200S is manufactured in the USA under US and foreign patents 6,717,681; 5,257,088; 5,094,528. Additional patents pending. Specifications are subject to change.

Laser Shearography Certifications AIA NAS 410, ASNT SNT-TC-1A, ASTM E2581-07, EN 4179

INSPECTION APPLICATIONS

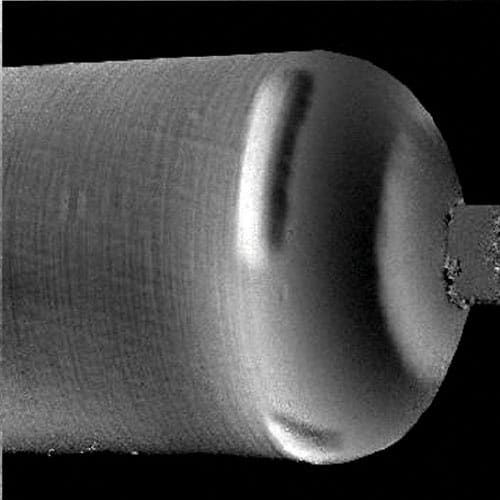

SHEAROGRAPHY IN ACTION

Shearography detects: Delaminations, Disbonds, Impact Damage, Repair Defects, Porosity, Cracks ,Fiber Waves or Wrinkles

OUR FULL LINE OF SHEAROGRAPHY NDT SYSTEMS

Shearography can be applied to many applications, if we don’t have a system that works for you, we can custom build one that will.