COMPACT DIGITAL SHEAROGRAPHY SYSTEM

5100

SHEAROGRAPHY SYSTEM

POWER AND VERSATILITY FOR ANY COMPOSITE

Remote Control Camera

Mode of Operation

Versitile Applications

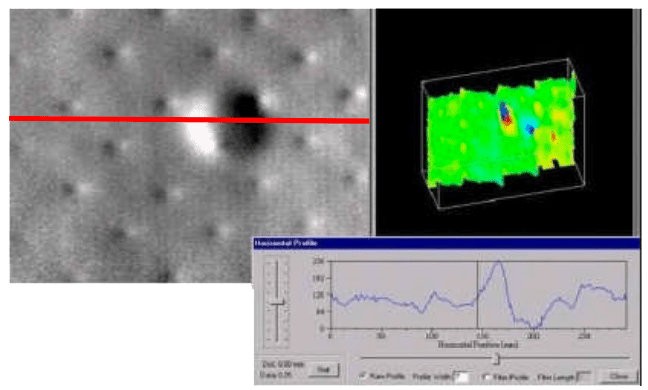

Powerful Image Processing

Speed

Laser Options

SPECIFICATIONS

Technical Description

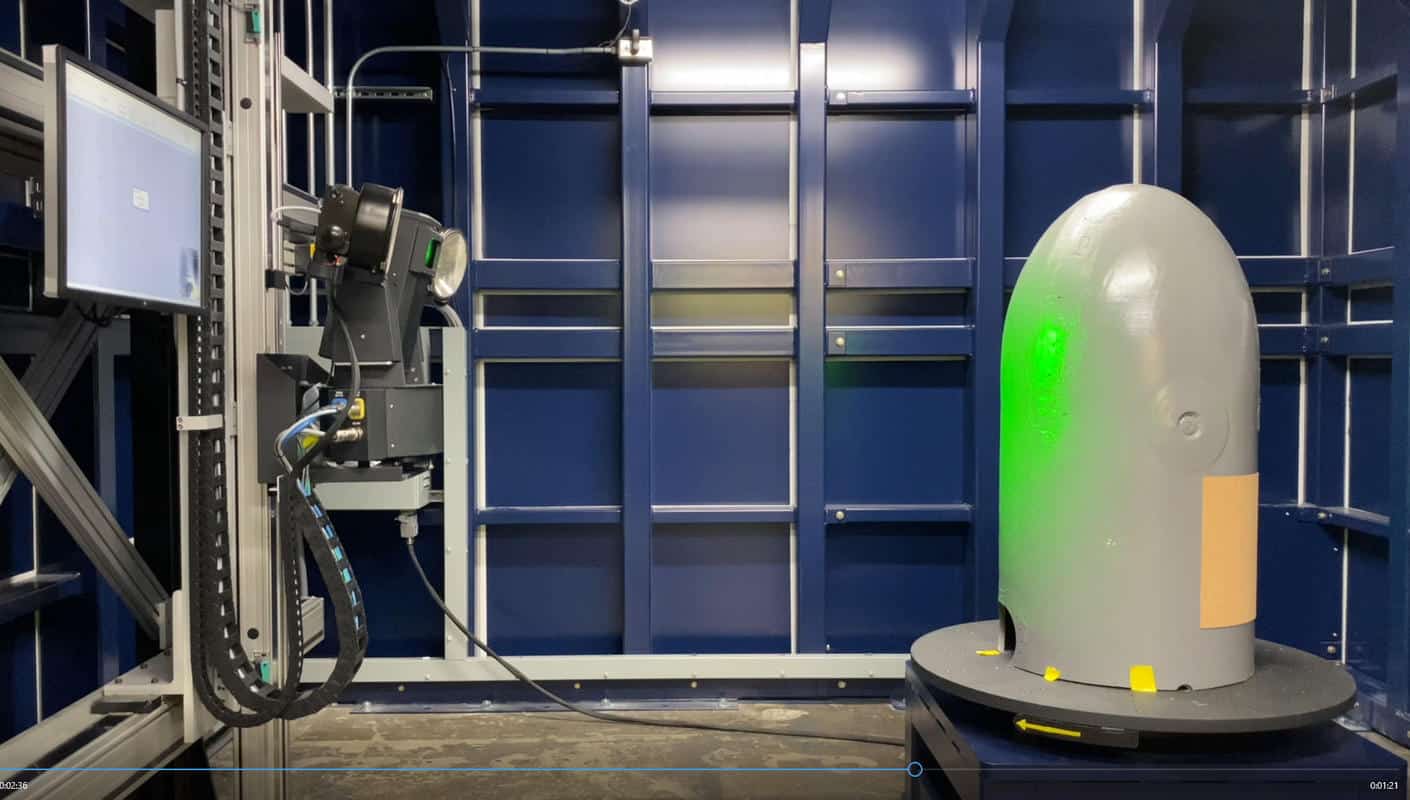

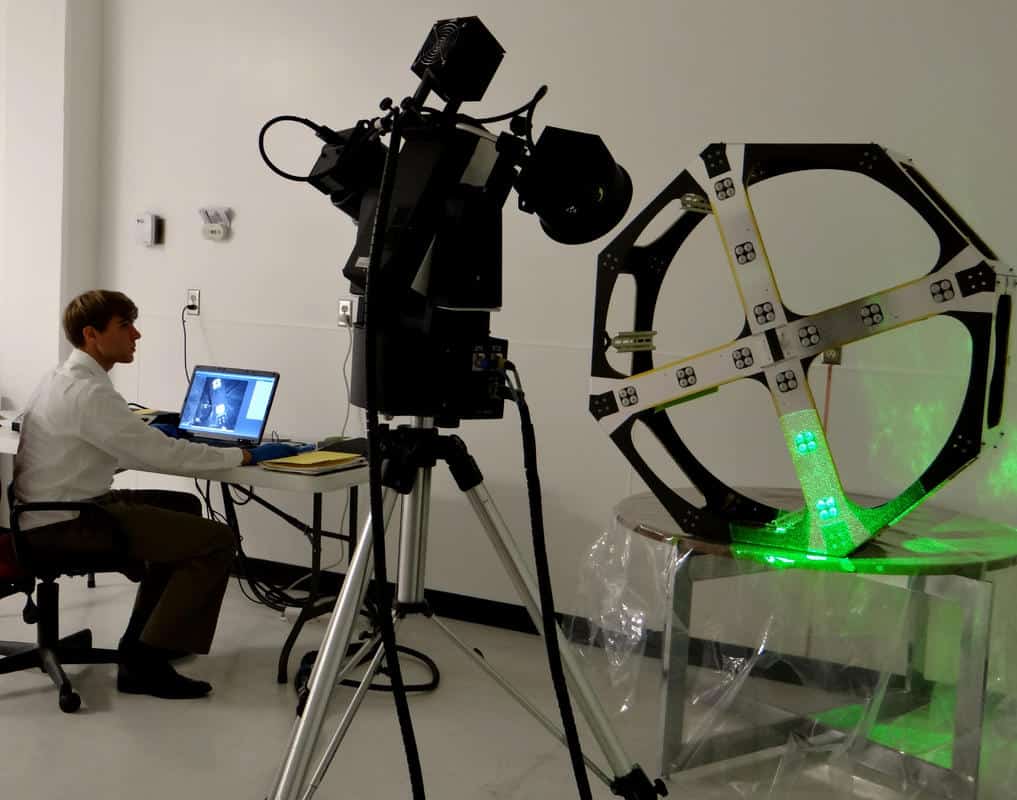

The LTI-5100 is a modular, all mode, digital Shearography Camera System featuring complete remote control of camera pan, tilt, zoom, iris, focus and shear vector as well as laser beam X/Y steering and beam expansion. The LTI-5100 consists of the SC-5100 Digital Shearography Camera with built-in or external laser, Remote Control Console, and the IP-5100 Image Processing Computer, all interconnecting cables, 2 Manuals and a One Year Warranty.

Optional Equipment

- Tripod and Adapter Plate

- MECAD-100, 200 Vibration Stress Units

- ACAD-100, 200 Acoustic Stress Units

- TS-100 Thermal Stress Unit

- Vacuum Windows and Generators

- LTI-9000 Vacuum Test Chambers

- Gantry and Mobile Lift Systems

Shear Camera Dimensions

Shear Camera

Sensor

Power

Operation Modes

Shear Vector

Measuring Sensitivity

0.05m/ shear distance

Image Calibration

Laser Light Source

Zoom

Computer and Remote Control Features

Manual Adjustments

System Software

Downloads

Patents: The LTI-5100 is manufactured in the USA under US and foreign patents 6,717,681; 5,257,088; 5,094,528. Additional patents pending. Specifications are subject to change.

Laser Shearography Certifications AIA NAS 410, ASNT SNT-TC-1A, ASTM E2581-07, EN 4179

INSPECTION APPLICATIONS

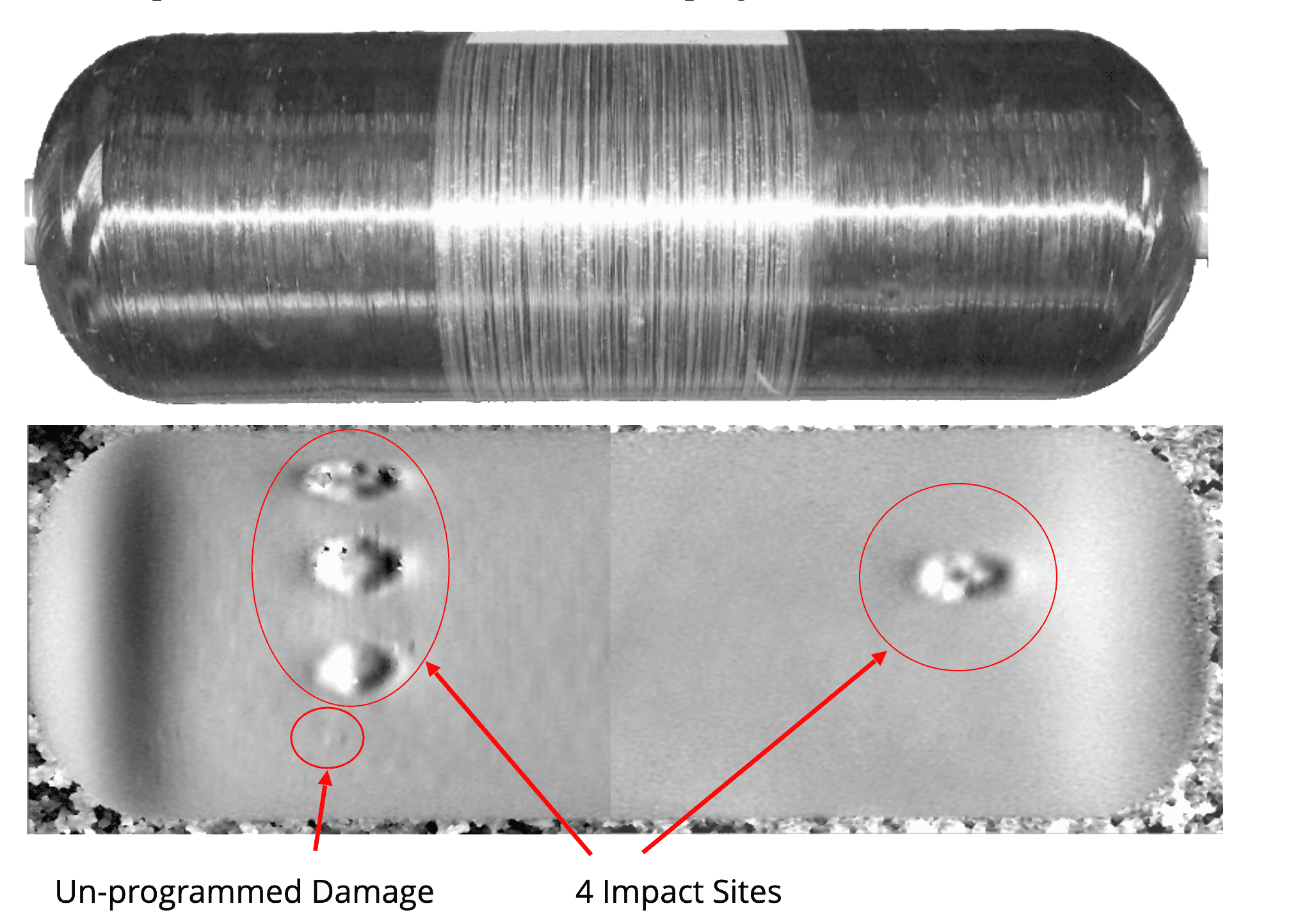

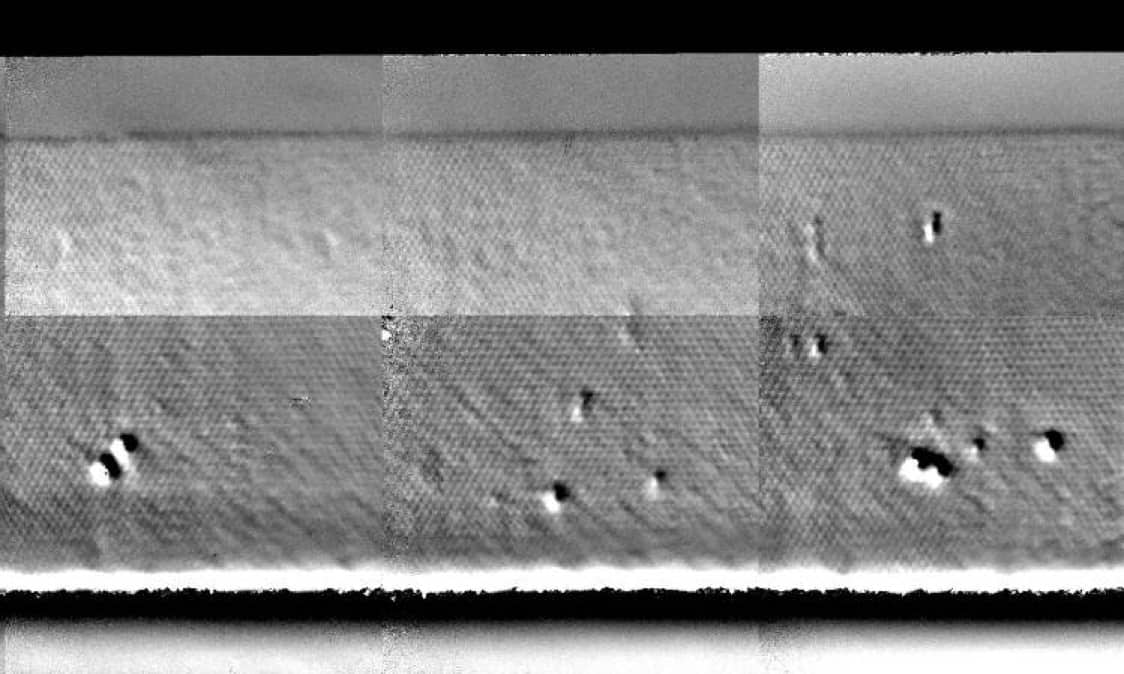

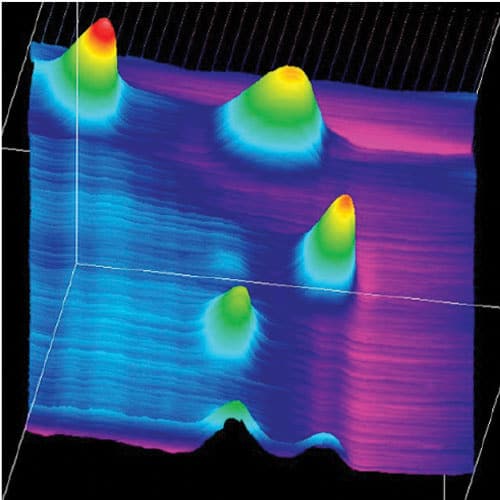

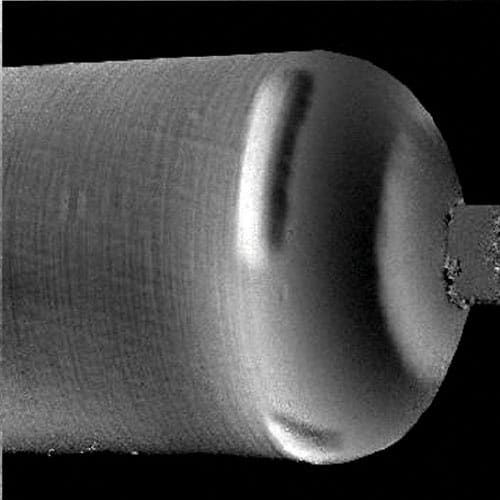

SHEAROGRAPHY IN ACTION

Shearography detects: Delaminations, Disbonds, Impact damage, Repair defects, Porosity, Cracks, Fiber waves or wrinkles

OUR FULL LINE OF SHEAROGRAPHY NDT SYSTEMS

Shearography can be applied to many applications, if we don’t have a system that works for you, we can custom build one that will.