SHEAROGRAPHY & HOLOGRAPHY NDT SYSTEMS

NDT Products

Laser Technology, Inc.’s products have evolved dramatically over the years to provide customers with cost effective, state-of-the-art NDT solutions, services and technical support. This commitment and our customer dedication have earned us the respect as the leader for laser shearography NDT for the Aerospace, Space, Marine, and Defense industries.

BENCHTOP, TRIPOD, GANTRY OR ROBOT MOUNTED SHEAROGRAPHY INSTRUMENTS

Tripod, Gantry Scanner Or Robot Mounting2100

Portability Meets Power and Versatility Designed for fast and accurate nondestructive inspection of structures, components and repairs.

Compact Digital Shearography System5100

All stress mode operation with programmable pan/tilt scanning and a powerful zoom lens.

PORTABLE, VACUUM ATTACHED

Shearography NDT System for Ciritcal Aerospace Components5200

Compact, portable vacuum shearography system designed for large area inspection of aerospace, marine and rail composite and cored sandwich structures and components.

Portable Thermal Laser Shearography6200

Vacuum attached compact, portable thermal shearography system designed for the nondestructive inspection of aerospace composite repairs, structures and components.

VACUUM SHEAROGRAPHY CHAMBERS

Large Chamber Shearography System9000

Vacuum Shearography System that includes the 5100 Shear Camera, Gantry, Part Fixture and Vacuum Test Chamber.

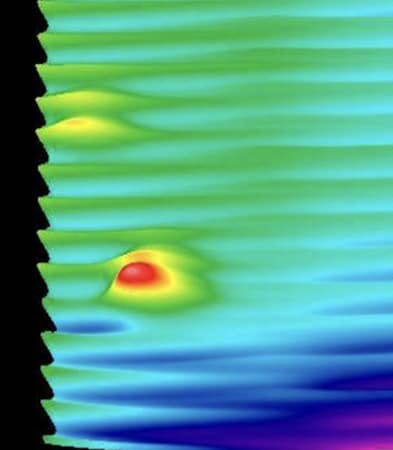

Shearography inside our purpose-built chambers provides exception throughput and disbond sensitivity for cored composite and metal structures such as helicopter blades, as well as bonded cork and elastomers.

Our 9000 Series Systems are single or dual channel with custom scan gantries or robots.

Sizes are in four ft. increments up to 20x20x40 ft. and are installed as turn-key systems.

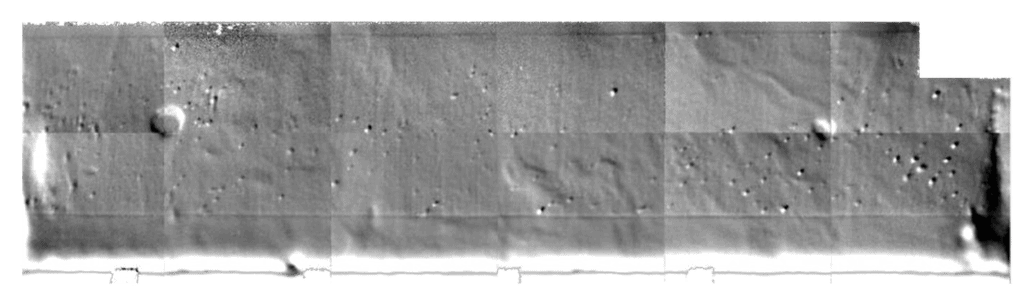

An aluminum honeycomb aircraft control surface Inspected with LTI-9000 in less than five minutes.

ROCKET ENGINE INSPECTION SYSTEMS

Liquid Propellant Rocket Engine Inspection SystemRTX-9500

Production inspection of regenerative cooled thrust chambers, nozzle and assemblies

HOLOGRAPHY

Digital Holography Inspection SystemDH-8000

Digital Holography Inspection System

CUSTOM SHEAROGRAPHY SYSTEMS

Get the help you needCustom NDT Solutions

Our years of Shearography experience can help you with feasibility, training and other NDT applications.